桑蚕丝丝绵生产加工技术研究进展

摘要: 桑蚕丝绵作为丝绵被的填充物,以其轻软、吸湿、舒适、不刺痒、保暖性好、弹性好等特点深受市场和消费者的青睐,由其制成的丝绵被不仅对人体皮肤及心血管有保健功效,还是重要的传统出口丝绸产品。然而以桑蚕丝为原料制作丝绵的过程中需要除去残余丝胶和油脂等杂质,以利于丝绵后整理工序的顺利进行。结合近年来制绵工艺及处理技术的一些研究成果,简要概述丝绵生产加工技术及功能性整理的研究进展,分析不同加工技术对丝绵的处理效果及制绵工艺中存在的问题,指出制绵的一些高新改进技术及开发具有高附加值的新型功能性整理。

关键词: 桑蚕丝;加工技术;制绵工艺;改进技术;功能性整理

中图分类号: TS143.2文献标志码: A文章编号: 10017003(2017)10001206引用页码: 101103

Research progress of the mulberry silk production and processing technology

LIN Haitao1, ZHAO Shuqiang1, LING Xinlong1, QIN Chaoxi2

(1. College of Biological and Chemical Engineering,Guangxi University of Science and Technology, Liuzhou 545006, China;

2. Guangxi Luzhai County Guisheng Cocoon Silk Industry and Trade Co., Ltd., Luzhai 545600, China)

Abstract: The mulberry silk which is used as a filler of silk floss quilt is deeply favored by the market and consumers because of the characteristics as softness, moisture absorption, comfort, not tickling, warmth retention property and good elasticity. The silk floss quilt which is made of the mulberry silk is not only good for human skin and cardiovascular health, but also an important traditional Chinese silk products for export. However, residual impurities such as sericin and grease need to be removed in the process of making silk floss with mulberry silk as raw materials so as to facilitate the silk floss finishing process. According to some research results of silk production and processing technology in recent years, the research progress of floss silk production technology and functional finishing are briefly summarized. Besides, the influence of different processing technologies on silk processing effect and the existing problems in the process of making floss silk are analyzed. Finally, some new improved technologies of silk production and the development of new functional finishing with high added value are pointed out.

Key words: the mulberry silk; processing technology; silk production; improved technology; functional finishing

1絲绵的概述

1.1丝绵的来源及加工流程

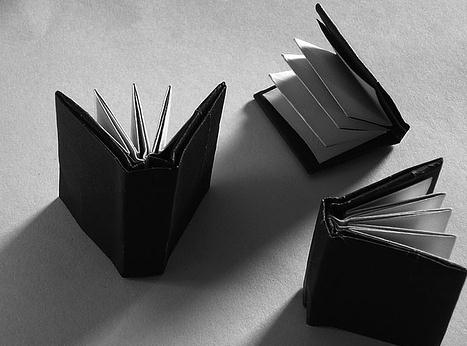

蚕茧经混、剥、选工序得到的一些下茧(如双宫茧),还有缫丝过程中产生的一些副产品(如蛹衬、汰头、滞头等)也可以作为丝绵的原料,如图1所示。手工丝绵传统上采用蚕茧为原料,经蒸煮、漂洗、剥茧开绵、晾晒或烘干等工序手工制作,如图2所示。随着蚕丝加工机械与设备的发展,当前的丝绵加工均采用机制丝绵的方式,经选茧、打绵、煮练、漂洗、晾晒或烘干等工序制成优良的丝绵被填充物,如图3所示。

2丝绵的性状特征

丝绵的加工方式有手工和机制之分,手工丝绵形状呈袋形且丝绵纤维呈网状交叉,存在丝筋和少量绵块,且含胶量很高;采用桑蚕丝制成的机制丝绵外形呈方形,而且很白。丝绵所用的原料不同,其特征也不同,比如用双宫茧加工的丝绵手感柔爽,没有明显绵块、丝筋;以次茧为原料制成的丝绵掺杂着很多茧屑和蛹皮[1]。丝绵中除了含有丝胶外,还有色素、油脂等杂质,丝绵使用一段时间后,会出现异味、丝绵板结等问题。为了使丝绵具有保暖、柔软、舒适等性能,在制作丝绵的过程中要严格控制好丝绵的含油率。另外,采购原料时,要确认其质量好坏,避免劣质原料流入生产线。

推荐访问: 桑蚕丝 丝绵 研究进展 生产加工 技术